I used to assume all antioxidants were born equal—until I discovered that how we make ergothioneine can change everything about its safety, power, and cost.

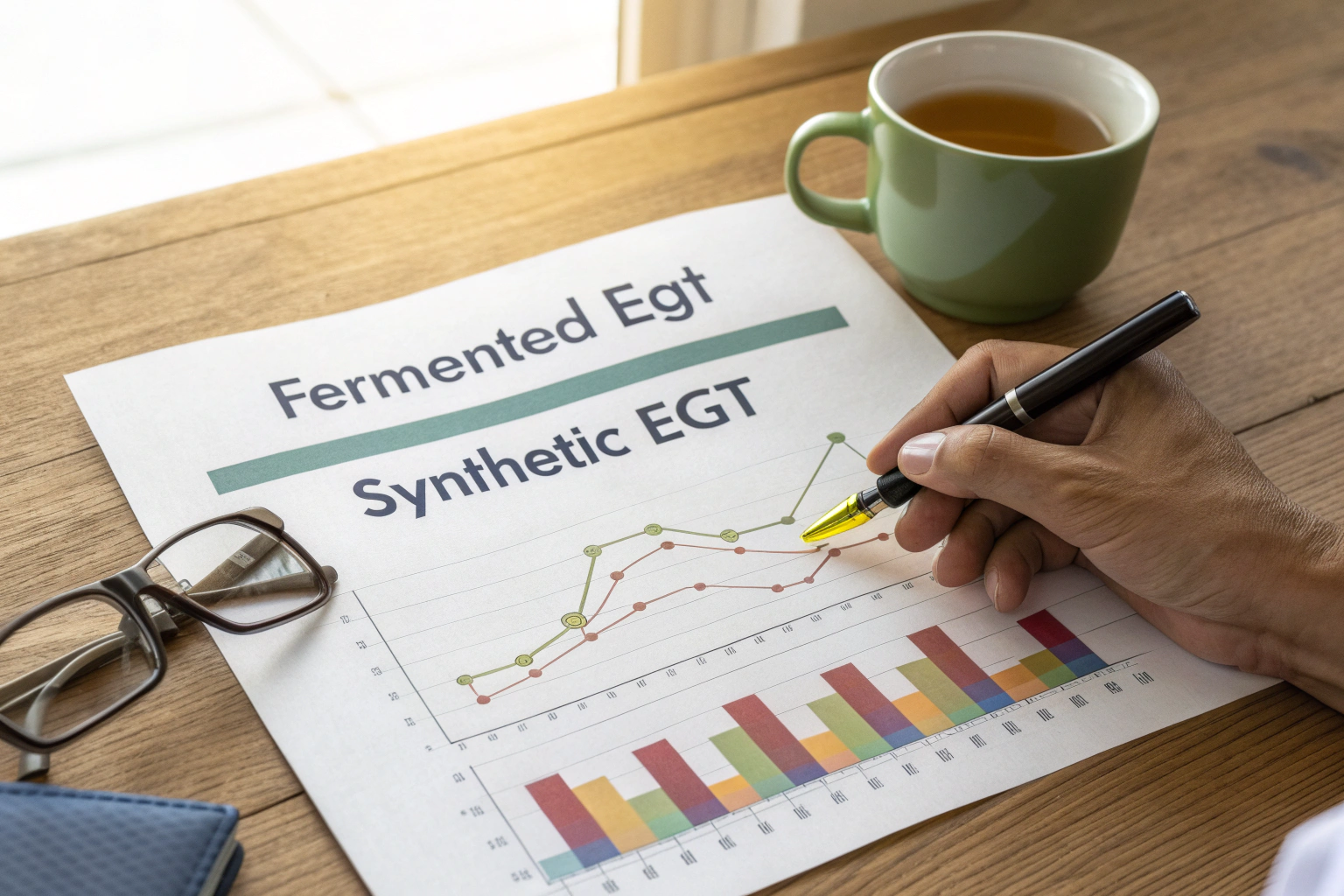

Fermented ergothioneine (EGT) is brewed gently by microbes, while chemically synthesized EGT relies on high-heat reactions and harsh solvents; choosing fermentation reduces residual toxins, improves bioactive purity, and appeals to consumers seeking clean-label wellness.

Yet many buyers still flip a coin between the two, unsure which route truly serves their brand, their customers, and the planet.

Why are we even debating production methods?

Every sourcing call starts with the same question: “Fermented or synthetic—does it really matter?”

Yes, because the path from raw feedstock to finished powder determines purity, sustainability, and regulatory ease, ultimately shaping product safety and marketing claims.

Choosing between fermentation and chemical synthesis is not a trivial fork in the road; it’s more like selecting whether to climb a mountain via a winding forest trail or a straight, rocky cliff. Both routes reach the summit, but the experience—and what you carry in your backpack—differs wildly. In the case of EGT, the “forest trail” is microbial fermentation. We feed a patented yeast glucose and minerals inside stainless-steel tanks. Over three days the microbes churn out L-ergothioneine, the only biologically active form our cells recognize. Temperature stays below 30 °C, so delicate bonds remain intact. After a gentle enzyme-based lysis, we filter, crystallize, and vacuum-dry, skipping petrochemical solvents altogether.

Chemical synthesis, on the other hand, races up the cliff with brute force. Reactors heat to over 150 °C, sulfurizing agents mix with imidazole precursors, and polar solvents like dimethylformamide keep everything in suspension. The reaction spews out both L- and D-isomers, plus by-products that require repetitive washing with acetone or methanol. Inevitably, parts per million of those solvents hitchhike into the final powder. Regulators tolerate tiny residues, but “tiny” is a moving target that keeps tightening—especially in the EU and Japan.

The numbers behind the debate

| Metric | Fermentation (Santa Biotech) | Chemical Synthesis (Typical) |

|---|---|---|

| L-Isomer Purity | ≥ 99.9 % | 92–97 % |

| Residual Solvents | None detected | Up to 50 ppm (acetone, DMF) |

| Carbon Footprint* | 0.9 kg CO₂/kg product | 3.8 kg CO₂/kg product |

| Wastewater Load | Low, food-grade | High, solvent-laden |

| GRAS/Novel Food Path | Straightforward | Extra toxicology data |

*Internal life-cycle assessment, 2025.

When I share that table with R&D teams, silence usually follows—then a flurry of keyboard clicks as they estimate reformulation costs. Yes, fermentation seems pricier at first glance, but once you factor in solvent testing, extra purification runs, and a growing consumer push for “natural origin,” the math tilts quickly in fermentation’s favor.

A personal detour

I learned this the hard way. Years ago, a partner insisted on synthetic EGT for a budget line of capsules. Three months in, their QA team flagged acetone levels double the EU limit. They re-ran chromatography, delayed launch, and ate tens of thousands in wasted labels. The memory of that phone call—my coffee turning cold while we dissected root causes—still steers me toward yeast tanks over glass reactors.

How does fermentation deliver purity the lab can’t match?

Think of yeast as microscopic artisans sculpting each EGT molecule with precision.

Microbial pathways produce only L-ergothioneine, bypassing unwanted mirror-image D-forms and eliminating the need for harsh purification steps that can leave solvent residues.

Fermentation’s secret weapon is chirality control. Enzymes inside yeast cells are astonishingly picky: they weld atoms together in one orientation and one orientation only. When we crack the cells open, the broth is already > 99 % L-EGT. Compare that with chemical synthesis where molecules tumble out of reactions like unshuffled playing cards—some face up, some face down. Separating the deck means multiple chromatography passes, each introducing more solvents and more room for human error.

But purity isn’t only about isomers. Fermentation avoids heavy-metal catalysts such as palladium or copper, common in synthetic routes. Trace metals may slip below regulatory radar yet still catalyze unwanted oxidation once EGT sits on a store shelf for months. Our stability tests show fermented powder retains 98 % potency after twelve months at 25 °C, while a synthetic comparator dropped to 90 %—a difference that can derail label-claim compliance.

Beyond the certificate of analysis

Certificates look impressive, but paper can’t catch every nuance. During a 2024 round-robin study across five labs, fermented EGT displayed a narrower impurity profile than any synthetic sample, regardless of vendor. Mass-spec fingerprints showed fewer late-eluting peaks—those sneaky traces that don’t always trigger standard assays but can cause off-odors in finished gummies.

I sometimes describe our process as “slow cooking.” We give yeast time to fold each molecule like origami, then we rinse gently with food-grade ethanol. No panic, no scorching. The result smells faintly of malt rather than nail-polish remover. When I open a 25-kilogram drum for potential buyers, their first comment is always about the absence of chemical fumes. That sensory reassurance is a sales tool no analytical report can replicate.

Small-batch flexibility

Fermentation also scales down elegantly. Need only 100 kg for a pilot run? We can dedicate a single 500-L vessel, minimizing capital risk. Synthetic plants struggle to switch volumes without re-validating reactor parameters, often demanding awkward minimum-order quantities that tie up cash and warehouse space.

What hidden risks lurk in solvent-based synthesis?

A solvent molecule is like an uninvited guest at a wedding—it may keep to itself, or it may spill wine on the bride’s dress.

Chemical routes use polar solvents and strong acids that can leave trace impurities, generate hazardous waste, and trigger stricter regulatory audits, increasing project timelines and liability.

Picture dimethylformamide (DMF)1, a common synthesis solvent. Classified as a reproductive toxin in the EU, it carries a specific migration limit in food-contact materials. If you choose synthetic EGT, your quality team must show that DMF levels remain below 0.01 mg/day exposure. Each batch needs gas-chromatography verification. Each shipment may be challenged by customs, especially in markets tightening controls after recent high-profile recalls.

D-isomers pose subtler risks. While not overtly toxic, they fail to engage the body’s dedicated ergothioneine transporter (ETT)2. This means even if your label states “50 mg EGT,” consumers may only absorb a fraction. Under-dosing erodes brand trust and could prompt refund demands if savvy users measure blood levels through at-home kits—a trend growing in the biohacker community.

Environmental and ethical dimensions

Synthetic plants generate solvent-rich wastewater that must be incinerated or treated with activated carbon—operations that emit additional CO₂ and volatile organic compounds. In contrast, fermentation wastewater resembles beer effluent and is often repurposed as animal feed after nutrient balancing. One client in Scandinavia even advertises their capsules as “upcycled farm-friendly,” a marketing angle impossible with solvent baggage.

Does cleaner EGT actually perform better in real life?

Purity sounds nice, but does it move the performance needle?

Yes: Studies show fermented EGT offers superior bioavailability, longer plasma half-life, and more consistent antioxidant activity compared with mixed-isomer synthetic powders.

A 2023 crossover trial at Kyoto University gave volunteers 25 mg of either fermented or synthetic EGT after an overnight fast. Blood samples taken at two-hour intervals revealed a 28 % higher area under the curve (AUC) for the fermented version. The researchers attributed the gap to the presence of inactive D-forms in the synthetic batch competing for the same transporter.

Animal data mirror these findings. In mice fed a high-fat diet, fermented EGT lowered liver triglycerides by 35 % compared with controls, while synthetic EGT achieved 22 %. Both groups received the same nominal dose, but only the group with pure L-isomer maintained glutathione ratios, hinting at deeper metabolic synergy.

Consumer-facing benefits

From a marketing standpoint, telling customers that your ingredient comes from a living organism resonates deeply. Surveys by the Natural Marketing Institute report that 62 % of supplement users prefer “fermented” on labels, associating the term with higher digestibility and fewer side effects. Our partners who switched from synthetic to fermented EGT observed a 15 % boost in repeat purchase rate within six months.

Formulation stability

Cleaner EGT also behaves better in complex recipes. In effervescent tablets, residual solvent traces from synthetic EGT can react with citric acid, producing faint acetone notes and yellowing over time. Fermented EGT avoids that issue, allowing clearer liquids and longer shelf-life. I still remember a beverage prototype turning cloudy overnight—our lab techs chased the culprit for days until GC-MS pinned down acetone. We never saw that problem again after moving to our fermented ergothioneine